Flanges For High Vacuum Tight

In the world of high vacuum equipment, there is often a need to make fixed couplings between mechanical components that can guarantee the necessary sealing conditions between a low-pressure environment and the atmosphere. This is the case, for example, of components of pumping systems, sensors, valves, viewports, electric and pneumatic feedthroughs, etc.

The most used standards nowadays, for the design of these couplings, are basically three: CF, KF and ISO. Let's see the general characteristics and the selection criteria.

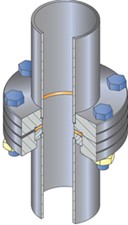

CF couplings

CF couplings (Conflat Flanges) are normally used for ultra-high vacuum applications, up to 10-13 mbar. They are available in a series of standardized nominal diameters, to facilitate the work of the designer (DN16, 40, 63, 100, 160, 200, 250) and consist of a pair of flanges, generally made of AISI 304L or AISI 316L stainless steel, materials suitable to be welded. The seal is guaranteed by the interposition, between the two flanges, of a partially or completely annealed oxygen-free copper (OHFC) sealing gasket, which is deformed by two teeth present on the flat faces of the opposing flanges. The gasket is housed in a special groove made on the flanges themselves, to facilitate assembly. The compression of the gasket takes place by tightening a series of bolts, placed along the circumference of the flanges, which are properly perforated.

In CF couplings, the copper gasket is disposable: in case of disassembly, it must therefore be replaced. The main advantages of this type of coupling are the very low level of outgassing and leakage of gases guaranteed by the metal on metal seal and the ability to withstand high baking temperatures of the equipment, a necessary prerequisite to be able to achieve extremely low base vacuum values. CF systems are in fact able to operate in a very wide temperature range, approximately between -196 ° C (liquid nitrogen temperature) and + 450 ° C, always guaranteeing excellent performance. For systems where resistance to high temperature thermal cycles (up to 500 °C) is required, silver-plated copper gaskets are available to reduce oxide formation.

On the other hand, it is a system that is rather laborious from the point of view of assembly (an example of a procedure can be seen for example on the website of the American company K. J. Lesker, at this address at this address). In addition, CF components are quite expensive and not suitable, due to their characteristics, for frequent assembly and disassembly.

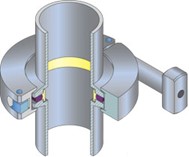

KF couplings

KF couplings are a valid solution in case relatively frequent reconfigurations of vacuum systems are necessary: it is in fact a coupling system classifiable as "fast". The KF joint is made through the use of a pair of flanges, each of which has a circular hollow capable of housing an O-ring (OR) that is interposed between the flanges themselves. The OR is equipped with a centering ring, which is also intended to reduce the probability of extrusion of the OR when it is subjected to the action of the pressure difference under conditions of high temperature. Since the seal is guaranteed by an elastomer, the maximum degree of vacuum that can be managed with KF couplings is of the order of 10-8 mbar, normally sufficient for most industrial applications. KF flanges are made of stainless steel or aluminum, and have a truncated conical profile, which allows the coupling through the use of terminals with an appropriate profile.

The maximum working temperature of KF couplings is limited by the material of which the OR is made (there is a wide variety of solutions available on the market): in the case of Viton, a commonly used perfluorinated elastomer, it is about 120 °C. The standard sizes available are as follows: KF10, KF16, KF25, KF40, and KF50, values corresponding to the internal diameter of the flange.

The main advantages of KF coupling systems is the speed with which they can be assembled and disassembled, and the low cost. On the other hand, they are not able to guarantee the performance of CF systems in terms of tightness and resistance to the high temperatures that may be present in certain processes. In addition, the diameters available for KF systems are limited to low values, typically used for some parts of pumping systems and for sensors.

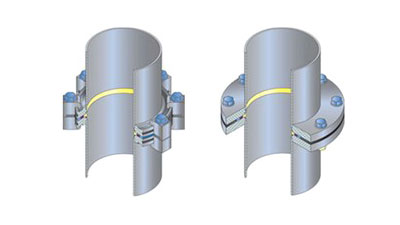

ISO couplings

The ISO couplings resume the design of the elastomer seals of the KF joints, with the difference that the coupling is achieved through bolts (in which case the flanges are perforated along their circumference) or multiple terminals (in which case the flanges have a circumferential groove in which the terminals can grip).

The standard sizes available on the market are 63, 80, 100, 160, 200, 250, 320, 400, 500, and 630, values corresponding to the internal diameter of the flange. The operating range, in terms of minimum manageable pressure value and minimum and maximum working temperature, is limited by the characteristics of the OR, and is substantially coincident with that of KF systems. However, these systems are designed to extend the practicality of the KF system to higher diameters.

Conclusions

The three high vacuum coupling systems described, CF, KF and ISO cover most of the design requirements for the tight joining of standard components. These joints are available, normally in stock, from the main manufacturers / distributors of vacuum components and therefore constitute a valid resource to reduce development times and increase the reliability and standardization of equipment operating in high vacuum.