Abbiamo scritto 18 articoli

Eliminate the water in a vacuum chamber by freezing it: is it possible?

- giovedý 8 ottobre 2020

The management of the "water load" in vacuum processing always represents a problem due to the molecular composition of the water. The use of cryogenic systems can help the elimination of the water present in vacuum deposition systems.

Vacuum: why?

- lunedý 6 luglio 2020

Vaccum processing needs the presencence of a particular environment. But why is a reduced pressure environment necessary and what are the pressures used in the vacuum technique? This are the reasons.

Stainless steel: why?

- lunedý 22 giugno 2020

If you have ever seen a machine for vacuum treatments, you will have noticed that the chamber in which the processing is carried out and a large part of the rest of the plant was made of stainless steel. But why, in these particular scientific and technological applications, is this material used? What are the advantages it offers (and what are the possible disadvantages)?

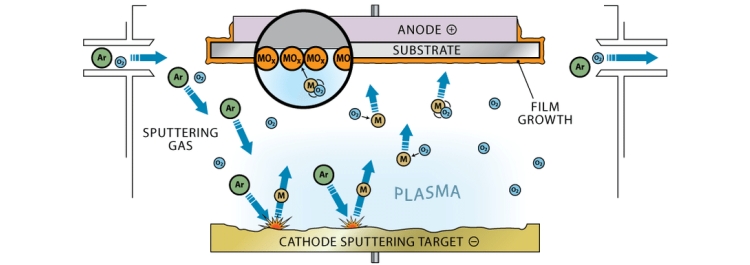

Magnetron Sputtering

- lunedý 9 settembre 2019

Magnetron sputtering has developed rapidly over the last twenty years, following the increasing industrial demand for high-quality functional films. Today, magnetron sputtering often outperforms other techniques used for the deposition of coatings of industrial interest.

Thin Films in everyday life

- mercoledý 26 giugno 2019

A brief description about how thin films have found application in everyday life.

The Role of Thin Film in Optical Field

- mercoledý 19 giugno 2019

Thin film coatings has found applications in mirrors, microscopy, photo catalysis, photovoltaic, solar cells, switches, lenses, microelectronics, etc.Optical thin films involves the interaction of electromagnetic radiation, at different wavelengths, with a deposited functional layer.

Vacuum Deposition Technologies

- lunedý 17 giugno 2019

Wide set of processes which are used by industry to deposit thin films, with a wide range of compositions and purposes, over substrate with largely variable composition, taking advantage of a high-vacuum environment.

The application of thin films in preventing corrosion

- venerdý 31 maggio 2019

The role of thin films in corrosion protection.